ForeShine -Fluidic Solution

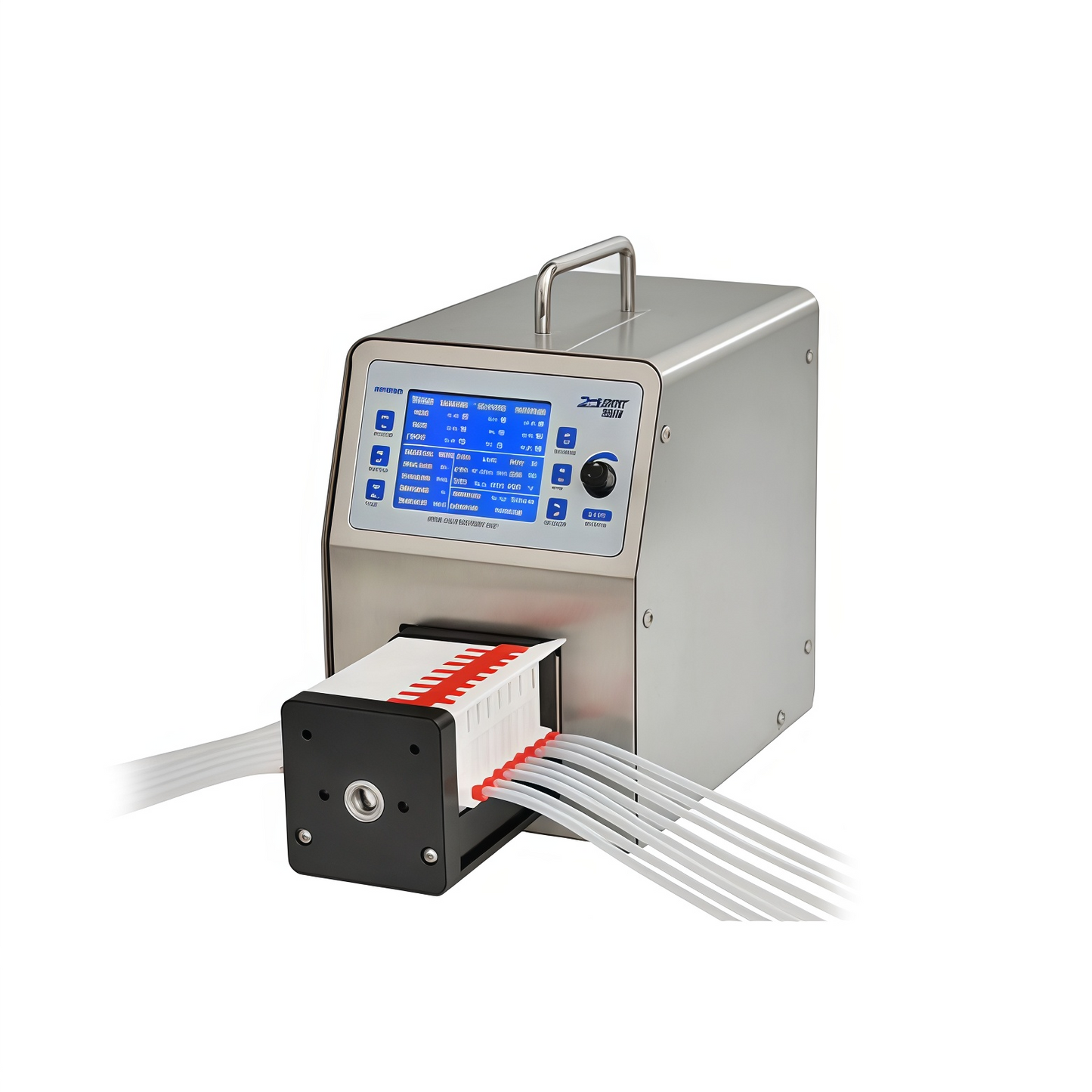

Precision Micro Flow Peristaltic Metering Pump - 8 Channels | BF400HMC8X

Precision Micro Flow Peristaltic Metering Pump - 8 Channels | BF400HMC8X

Не удалось загрузить сведения о доступности самовывоза

BF400H/MC8X

Experience precise metering and filling with our 8-channel Precision Micro Flow Peristaltic Metering Pump. Ideal for industrial use, this pump offers superior performance and control.

Key Features:

- 8 independent channels for precise metering

- Micro flow rates for accurate filling

- External control for easy operation

- Durable construction for industrial use

Using tubing:Inside diameter range:0.19-3mm;wall range:0.7-1.1mm

Flow:0.0002-25mL/min(0.1-100rpm)

Number of channels: 1, 2, 3, 4, 5, 6, 8, or can be combined in series, for example, 8+8=16, the link is for 8 channels ,each channels comes 1 meter silicon tubing as picture, if you need the tubing to be BPT or Viton or others to resist the corrosive liquid, contact us freely.

Application: Commonly used for small dose multi-channel dispensing and transmission of various liquids,

such as pharmaceutical, food, chemical, biological, laboratory and other industries; thinner tubes can be used, and the

pump head is 8 rollers, so as to achieve for small flow transmission and sub-packing, the number of channels that can be

selected is more flexible; the cam structure is used to install the tubing conveniently and quickly.

Characteristic

1. 3.5-inch 320*240 high-brightness LCD display, all operating parameters are displayed on the same screen, the

operation is simple and easy to understand.

2. Adopt "dual CPU" control, drive and control separation, fast operation speed, stable operation, high transmission

accuracy, accurate one-key filling function, repeatability up to ±0.5%.

3. It has the functions of automatic flow correction, sound reminder, stepless speed regulation, start-stop, reversing

and other functions. It is equipped with a full-speed button and has fast filling and emptying functions.

4. It has two working modes: distribution mode and transmission mode; three distribution modes: flow distribution,

time distribution and copy distribution; the suction angle can be set arbitrarily within 720°.

5. Abundant external control functions are available. For example, the DC12V output is convenient for direct

connection to a variety of sensors, capacitive sensors, liquid level sensors, photoelectric sensors, etc.; the product

hardware reserves a variety of circuit interfaces to meet the special customization needs of customers.

6. A stepping motor is used to control the rotation speed, which is not affected by the load change, high torque, low

power consumption, and strong adaptability.

7. The driving circuit has excellent performance, good heat dissipation, low working noise, stable operation, and

power-down memory function. The internal circuits are all three-proof treatment, anti-interference, wide voltage

design, suitable for complex power supply environment.

8. BF-H series products have handles and are easy to carry; various pump heads can be installed.

9. The roller device adopts full ball bearing design, supports high-speed operation, long life, stable operation and

low noise.

10. The pressing block and the base are formed at one time by the machining center, with high dimensional

accuracy and precise flow.

11. The card material is imported POM, which has high wear resistance, high dimensional accuracy and long

service life.

12. The card adopts a cam structure, opened from above, easy to disassemble, easy to replace and fix the tubing,

the pressure can be fine-tuned to adapt to tubs with different wall thicknesses, and the application is flexible.

13. Multi-channel transmission. When the driving capacity permits, multiple pump heads can be connected in series

and multiple drivers can be connected.

14. The roller device is made of 304 stainless steel, which is suitable for occasions with high requirements of complex environment and hygienic level.

Flow rate sheet

|

MC8X |

0.19*0.9 0.25*0.9 0.5*0.8 1*1 2*1 2.4*0.85 2.79*0.85 |

(≤100rpm) 0.0002-0.2 (≤100rpm) 0.00035-0.35 (≤100rpm) 0.0013-1.3 (≤100rpm)0.0053-5.3 (≤100rpm)0.015-15 (≤100rpm)0.0185-18.5 (≤100rpm)0.025-25 |

Technical Parameters

- Product Model: BF400H

- Speed Range: 0.1 - 100 rpm

- Flow Rate Range: 0.025-25ml/min

- Rollers: 8

- Roller Material: SS304

- Shell Material: Aluminum alloy+POM

- Pressure adjust: Yes

- Pressure: According to lever position (for low pressure application)

- Full bearing : Yes

- Speed Resolution: 0.1 rpm (≤ 100 rpm); 1 rpm (≥ 100 rpm)

- Accuracy Error: Flow rate accuracy error: ±0.5%; Repeatability accuracy error: ±0.3%

- Dispensing Time: 0.1 - 999.9 s

- Dispensing Volume: 15μL-9999L

- Dispensing Cycles: 1 - 9999 times (0 times for infinite loop)

- Interval Time: 0.1 - 999.9 s

- Display: 3.5-inch 320*240 high-brightness LCD screen

- Operation Method: Membrane keys + digital adjustment knob

- External Speed Control Methods: 4 - 20 mA (standard), 0 - 10 K (standard), 0 - 5 V (optional), 0 - 10 V (optional); Customized special signal speed control methods are also available (Before placing an order, please make sure that the standard configuration options meet your requirements.)

- External Control Types: External start/stop, external direction change [TTL 5V signal (standard), TTL 12V signal (optional), TTL 24V signal (optional); Customized special level signals are also available] (Before placing an order, please make sure that you have selected the external control mode.)

- Port Output: DC12V power output; DC5V level signal output

- Communication Interface: RS232, RS485 (for controlling the driver's start/stop, direction change, speed, etc.)

- Power Supply: AC220V ± 10%, 50Hz/60Hz; AC110V ± 10%, 50Hz/60Hz (optional); AC380V ± 10%, 50Hz/60Hz (optional) (Before placing the order, please make sure to confirm the power voltage you require.)

- Power Consumption: ≤ 45W

- Operating Environment: Ambient temperature 0 - 40℃, relative humidity ≤ 80%

- Protection Grade: IP31

- Weight: 5.8 kg

Share